Aluminum Alloy Sheets For Closure Caps 3105 8011 5182

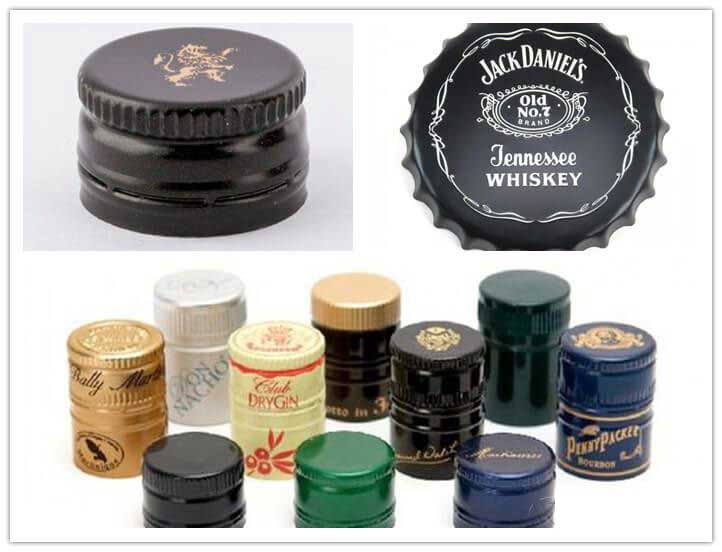

Aluminum alloy sheet for closure caps usually refers to the aluminum alloy used to produce packaging materials such as bottle caps and can lids.

Aluminum alloy sheet for closure caps usually refers to the aluminum alloy used to produce packaging materials such as bottle caps and can lids. Aluminum alloy sheets are widely used in the food and beverage packaging industry because of their lightweight, corrosion-resistant and easy-to-process properties.

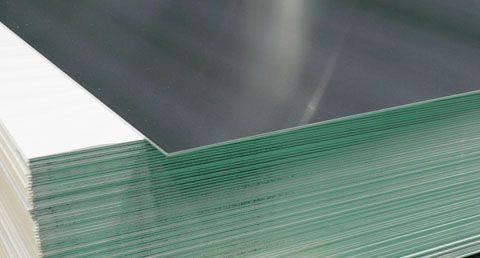

Common aluminum alloy series of aluminum sheet for closure caps are:

- 1060 Aluminum Alloy: belongs to the pure aluminum series, has good elongation as well as tensile strength, can meet the conventional processing requirements (stamping, stretching), high formability. Commonly used in the production of aluminum cover raw materials, because of its easy to stretch, stable performance, smooth and delicate surface.

- 3105 Aluminum Alloy: This is a newer aluminum alloy designed for packaging applications, especially beverage cans and bottle caps. It offers good workability and surface quality while maintaining adequate hardness and corrosion resistance.

- Aluminum Alloy 5052: This alloy is also being considered for use in the manufacture of certain types of bottle caps due to its excellent corrosion resistance, high strength, and good machinability. It consists primarily of magnesium and chromium, and is copper-free, which makes it perform particularly well in salt spray environments.

- Aluminum alloy 5182: This alloy is mainly used for easy-open caps (e.g., pull-tab lids for beverage cans) because of its excellent deep-drawing properties and high strength, while maintaining good corrosion resistance. The main alloying element it contains is magnesium.

- Aluminum alloy 8011: This alloy is particularly suitable for use in the food packaging sector, especially for applications requiring good coating adhesion. It has iron and manganese as the main alloying elements and is widely used because of its excellent chemical resistance. It is suitable for the production of bottle caps, especially for alcohol, beverages and pharmaceuticals.

The alloy temper of aluminum sheet for closure caps is generally H14 and H16, and the thickness range is generally between 0.15 mm and 0.3 mm. As the good performance, aluminum closure sheet are wide applied in packaging industry, and the specific uses are:

- Beverage bottle caps: such as carbonated drinks, fruit juice, alcohol and other aluminum alloy bottle caps.

- Food can caps: such as aluminum alloy caps for canned vegetables, meat, etc.

- Pharmaceutical packaging: sealing caps for pharmaceutical bottles to ensure the safety and effectiveness of drugs.

- Cosmetic packaging: aluminum alloy is also used for certain cosmetic bottle caps to enhance the sense of class and anti-corrosion ability of the product.

These aluminum alloys are widely used in the manufacture of closure caps for beverage, food, pharmaceutical and other industries due to their lightweight, corrosion-resistant and easy-to-process characteristics. Aluminum alloy caps are widely used in the packaging industry because of their excellent characteristics, which can effectively extend the shelf life of products and maintain their quality. When choosing an aluminum alloy sheet for closure caps, factors such as the purpose of the cap, the required strength, sealing properties and production costs are usually taken into consideration.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531