Anodized Aluminum Reflector Sheet

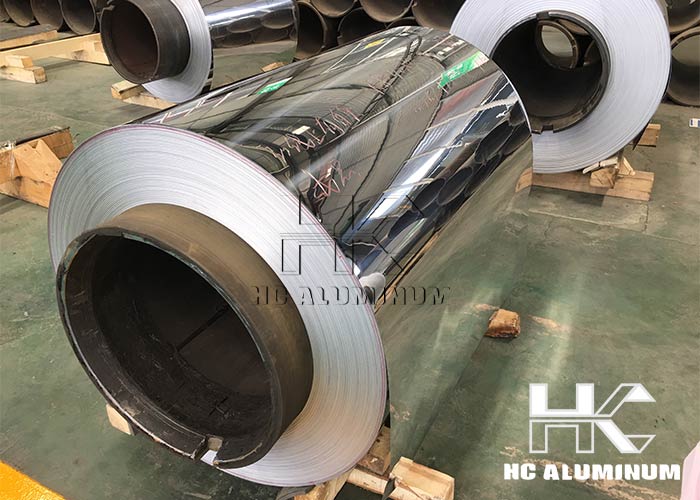

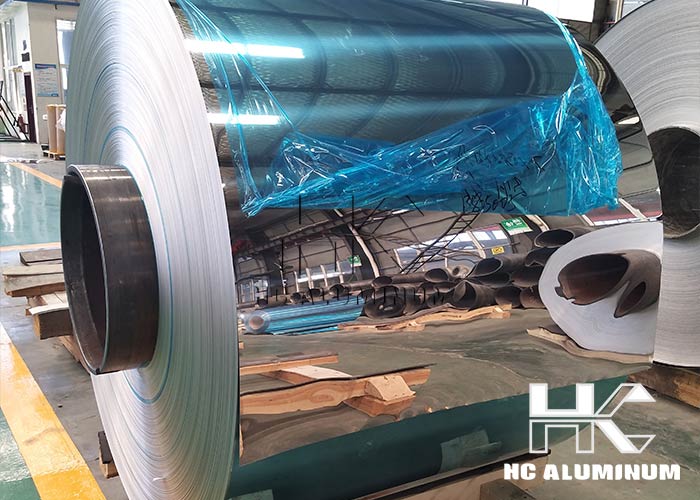

Anodized aluminum reflector sheets are aluminum treated through anodizing and mirror polishing process, resulting in excellent reflective properties and corrosion resistance.

Anodized aluminum reflector sheets are aluminum treated through anodizing and mirror polishing process, resulting in excellent reflective properties and corrosion resistance. Anodizing is an electrochemical process that forms a dense aluminum oxide film on the aluminum surface, enhancing its wear resistance and oxidation resistance.

Alloys of Anodized Aluminum Reflector Sheet

- Pure Aluminum Series (1××× Series)

Representative Models: 1050, 1070, 1085

Properties: Aluminum content ≥99%, excellent conductivity and corrosion resistance, but lower strength, making them suitable for applications requiring high flatness (such as precision optical reflectors).

Applications: Indoor lighting reflectors, solar collectors.

- Aluminum-Magnesium Alloy Series (5××× Series)

Representative Models: 5052, 5005

Properties: 3-5% magnesium content, 30% increased strength, and significantly enhanced weather resistance, making them suitable for outdoor environments.

Applications: Architectural curtain walls, automotive headlights.

Thickness Parameters of Anodized Aluminum Reflector Sheet

- Substrate Thickness

General Range: 0.5mm-5.0mm, including:

0.5mm-1.5mm: for electronic equipment and interior decoration;

2.0mm-5.0mm: for building curtain walls and traffic signs.

- Oxide Film Thickness

Ordinary Oxidation: 5-10μm, suitable for indoor environments, with a salt spray resistance of 500-1000 hours;

Hard Oxidation: ≥25μm, suitable for coastal/industrial areas, with a salt spray resistance exceeding 3000 hours.

Abrasion Resistance: Wear resistance increases approximately 30% for every 10μm increase in film thickness.

Colors of Anodized Aluminum Reflector Sheet

- Solid Colors: Silver, Gold, Black (achieved through electrolytic coloring);

- Metallic Colors: Titanium, Rose Gold, Champagne (by adding organic dyes or metal salts).

Process Flow of Anodized Aluminum Reflector Sheet

Pretreatment: Degreasing → Alkali Etching → Neutralization → Polishing (Mechanical/Chemical);

Anodizing: In sulfuric acid electrolyte, voltage 14-18V, time 20-60 minutes;

Coloring: Electrolytic coloring (penetration type) or dye immersion (adsorption type);

Sealing: Hot water sealing or nickel salt sealing to improve corrosion resistance.

Features of Anodized Aluminum Reflector Sheet:

- High Reflectivity: After anodizing, the aluminum surface is smooth and has high reflectivity, making it suitable for optical equipment and lighting reflectors.

- Corrosion Resistance: The oxide film effectively prevents aluminum from oxidation, extending its service life in humid or corrosive environments.

- Aesthetics: Anodizing can create a variety of colors and textures on the aluminum surface, enhancing the product's aesthetics.

- Wear Resistance: The oxide film's high hardness improves the aluminum's wear resistance.

Typical Application

- Architecture

Curtain Wall Decoration: mirrored aluminum composite panels with a reflectivity of 92% and energy savings of 30%;

Indoor Ceiling: The platform roof of uses anodized aluminum sheets with a 10-year weather resistance.

- Lighting and Energy

LED Reflectors: Super-mirror aluminum sheets offer a reflectivity of 95%, increasing light efficiency by 20%;

Solar Thermal Collectors: 5052 anodized aluminum mirror sheets with a stable heat absorption efficiency of over 85%.

- Transportation and Electronics

Automotive Lampshades: Hard anodized mirror aluminum sheets are stone-impact resistant and have a lifespan of 10 years;

Mobile Phone Middle Frames: Rose gold anodized aluminum sheets with a wear resistance that has passed 1,000 steel wool tests.

- Special Environments

Chemical Equipment: The 25μm oxide film is resistant to acid and alkali corrosion and is suitable for offshore platforms;

Medical Equipment: After sterilization, it is used in surgical light reflector systems.

When processing and using anodized aluminum reflector sheet, avoid scratches and collisions to prevent damage to the surface oxide film.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531