Anodized Black Aluminum Sheet

Anodized black aluminum sheets are high-performance materials produced by forming an oxide film on the surface of aluminum alloys through an electrochemical method and then dyeing it black.

Anodized black aluminum sheets are high-performance materials produced by forming an oxide film on the surface of aluminum alloys through an electrochemical method and then dyeing it black. They possess protective, decorative, and functional properties and are widely used in high-end manufacturing. Anodizing is a commonly used aluminum surface treatment technology that improves the corrosion resistance, wear resistance, and aesthetics of aluminum materials.

Process principle of anodized black aluminum sheet:

- Anodizing:

Using an aluminum sheet as the anode, it is placed in an electrolyte such as sulfuric acid or chromic acid. After energizing, a porous alumina film with a thickness of 5-25 μm is formed on the surface. This film consists of a dense barrier layer and a porous outer layer, achieving a hardness of over HV300 and a melting point as high as 2320K. It possesses properties such as corrosion resistance, wear resistance, and insulation.

- Dyeing treatment:

The oxide film is dyed black through electrolytic coloring or organic dyeing.

Electrolytic coloring: The anodized aluminum sheet is immersed in an electrolyte containing heavy metal salts such as tin salts and nickel salts. Metal ions are deposited in the micropores of the oxide film, forming a stable metal oxide layer with strong color durability.

Organic dyeing: Water-soluble organic dyes are used to penetrate the pores of the oxide film to achieve uniform coloring, but fading is likely under long-term UV exposure.

- Sealing treatment:

The pores of the oxide film are sealed using hot water or chemical solutions, improving corrosion resistance and stain resistance, and preventing color seepage.

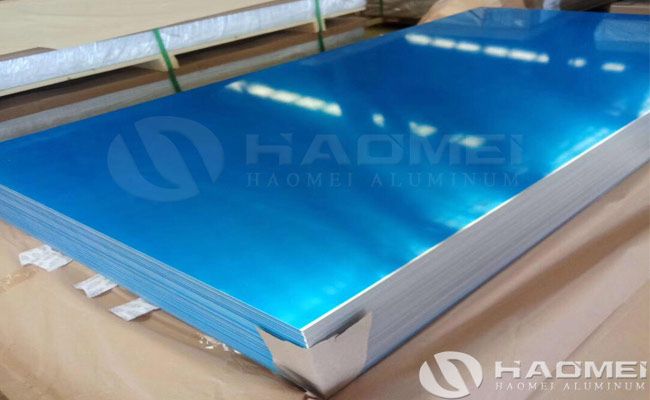

Specifications of anodized black aluminium sheet:

- Material:

Commonly used aluminum alloys include 6061, 6063, and 5052. Different aluminum alloys have different mechanical properties and corrosion resistance.

- Thickness:

The thickness of aluminum sheets is typically between 0.5mm and 10mm, depending on the application.

- Dimensions:

Standard black anodized aluminum sheet dimensions are typically:

Length: 1000mm, 2000mm, 2500mm, etc.

Width: 1000mm, 1250mm, 1500mm, etc. Custom sizes are also available upon request.

- Oxide film thickness:

The thickness of the anodic oxide film is typically between 5μm and 25μm, with special requirements allowing for thicknesses of 50μm or more.

- Surface treatment:

The surface of black anodized aluminum sheets can be smooth, brushed, or matte, depending on customer requirements.

- Performance standards:

The performance of anodized aluminum sheets typically meets relevant industry standards, such as ASTM and GB/T.

Performance advantages of anodized black aluminum sheet:

- Corrosion resistance:

The oxide film and sealing treatment significantly enhance the corrosion resistance of the aluminum sheet in humid and acidic/alkaline environments, showing no corrosion after thousands of hours of salt spray testing.

- Abrasion resistance:

The oxide film has high hardness and strong scratch resistance, suitable for high-frequency contact applications.

- Decorative properties:

Matte or glossy effects are available, with a uniform and deep black appearance, meeting high-end design needs.

- Insulation:

The oxide film is a non-conductive material, suitable for electrical insulation applications.

- Thermal stability:

Excellent high-temperature resistance; does not burn or peel at high temperatures, and does not discolor with long-term use.

- Color fastness:

Products colored with inorganic dyes or metal salts have strong UV resistance, ensuring color stability over long-term outdoor use.

- Environmental protection:

The process is non-toxic and harmless; the aluminum sheet is recyclable, meeting environmental protection requirements.

Application areas of anodized black aluminum sheet:

- Electronic products:

Casings for mobile phones, tablets, and laptops, utilizing their lightweight, heat dissipation, and corrosion resistance.

- Automotive industry:

Body panels, engine parts, wheels, etc., enhancing wear resistance and aesthetics.

- Aerospace:

Aircraft shells and engine components, meeting the requirements for high strength, corrosion resistance, and lightweight design.

- Architectural decoration:

Curtain walls, doors, windows, railings, etc., combining a modern metallic feel with weather resistance.

- Industrial equipment:

Mechanical parts and tool housings, utilizing their wear resistance and chemical corrosion resistance.

- Medical equipment:

Wheelchairs, crutches, oxygen cylinders, etc., meeting the requirements for sterility and impact resistance.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531