Coated Coil Sheet Aluminum 8011 H14 Alloy For Bottle Caps

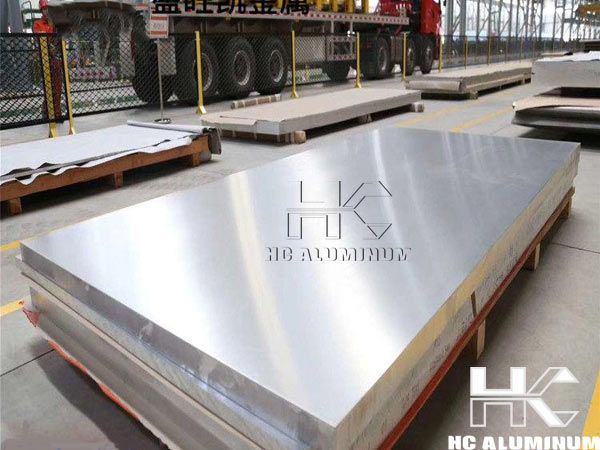

The coated coil sheet aluminum 8011 h14 alloy is the ideal material choice for bottle cap manufacturing because of its unique material properties and processing advantages.

The coated coil sheet aluminum 8011 h14 alloy is the ideal material choice for bottle cap manufacturing because of its unique material properties and processing advantages.

The following are detailed reasons for its suitability as bottle cap material:

1. Excellent mechanical properties

- High strength and toughness

8011 H14 aluminum alloy is cold rolled (H14 temper indicates semi-hard state), which significantly improves tensile strength and tear resistance while maintaining good ductility. It is able to withstand the mechanical stresses of stamping and stretching during bottle cap processing, reducing the risk of breakage.

- Abrasion resistance

Its surface hardness is moderate, suitable for high-frequency opening and closing use, to avoid friction caused by coating peeling or deformation.

2. Chemical properties and protection

- Corrosion resistance

Fe (iron) and Si (silicon) elements are added to 8011 aluminum alloy to enhance the corrosion resistance of the material, which is especially suitable for bottle caps that come into contact with liquids (e.g., liquors, medicines, beverages) to avoid oxidization or chemical reaction affecting the sealing.

- Barrier properties

Aluminum 8011 has an excellent barrier effect against oxygen, moisture and light, effectively extending the shelf life of the contents. Coatings (e.g. chrome treatment) further enhance moisture and permeation resistance, making it suitable for pharmaceutical or food packaging that needs to be stored for a long period of time.

3. Processability

- Deep-drawing moldability

Coated coil and sheet aluminum 8011 h14 alloy has a low lugging rate (high edge uniformity during forming), which makes it suitable for the stamping of complex shaped bottle caps, such as anti-theft rings, threaded caps and other precision structures, to ensure that the cap fits tightly with the mouth of the bottle.

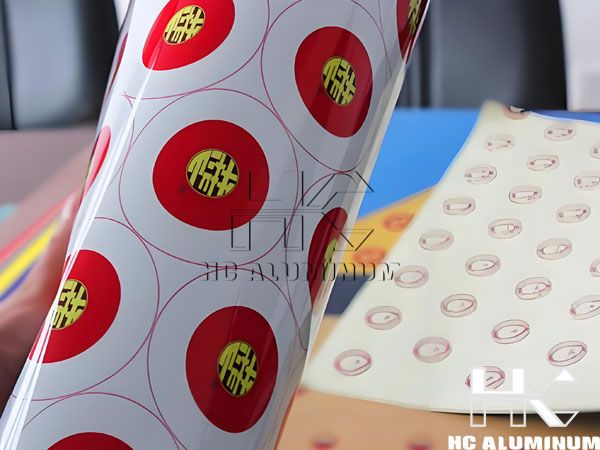

- Coating compatibility

The clean surface and non-flecking characteristics make it easy to be coated with paint, printed or laminated to meet the diversified needs of brands for the appearance of bottle caps (e.g. embossing, color marking).

4. Safety and environmental protection

- Non-toxic and hygienic

8011 aluminum sheet for bottle caps meets the standards of food-grade and pharmaceutical-grade packaging, with no harmful substances precipitated, and is suitable for bottle caps that come into direct contact with medicines and food (e.g., caps for oral liquid bottles and milk powder caps).

- Recyclability

Aluminum can be recycled to reduce the burden on the environment, in line with the global trend of green packaging.

5. Economy and wide application

- Cost-effectiveness

8011 aluminum alloy raw materials are easy to obtain, high processing efficiency and high yield rate, suitable for mass production, reducing the cost of bottle cap manufacturing.

- Multi-field application

From wine (red wine, white wine bottle caps) to pharmaceutical (oral liquid caps), food (yogurt caps, beverage caps) and even cosmetic caps, 8011 H14 can be adjusted to meet different needs by adjusting the coating or thickness (commonly 0.02-0.23mm).

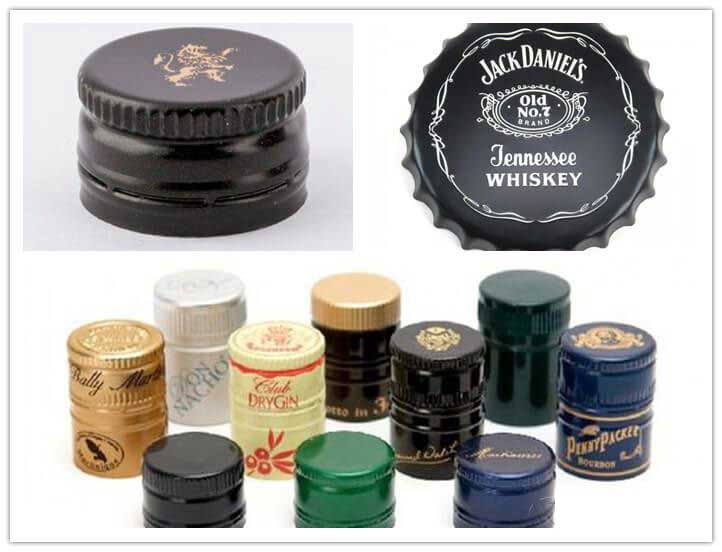

Typical applications of coated coil and sheet aluminum 8011 h14 alloy in bottle caps:

- Pharmaceutical bottle caps: such as oral liquid aluminum sealing, need high temperature sterilization treatment, 8011 H14's high temperature resistance and sealing to protect the safety of drugs.

- Anti-theft wine bottle caps: anti-theft rings are formed by stamping, relying on the strength and toughness of the material to prevent tampering.

Coated coil and sheet aluminum 8011 h14 alloy has become an ideal choice for bottle cap materials due to its comprehensive properties such as high strength, corrosion resistance and easy processing, combined with coating technology to further enhance protection and aesthetics. Its wide range of applications in the food, pharmaceutical, and liquor industries validates its balance of functionality, safety, and economics.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531