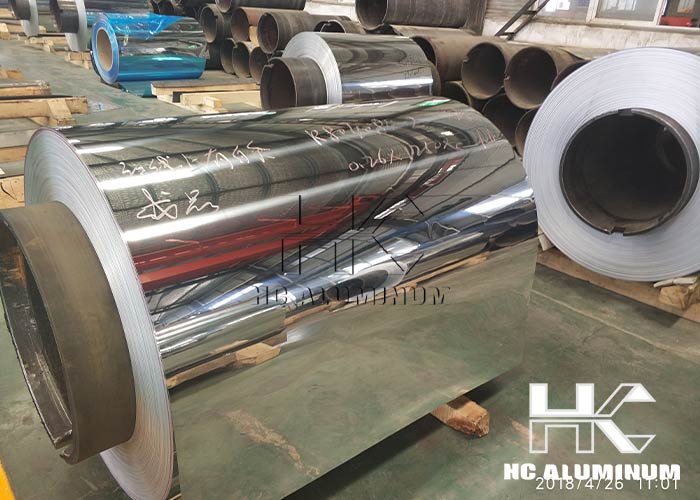

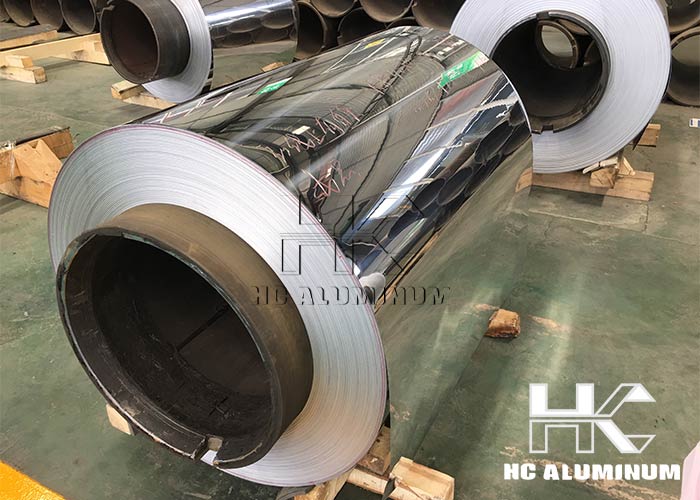

Wide Application of Mirror Aluminum Sheet

Mirror aluminum sheet, with its core advantages of high reflectivity, lightweight, easy processing, weather and corrosion resistance and aesthetic appeal, has found widespread application across multiple industries.

Mirror aluminum sheet, with its core advantages of high reflectivity, lightweight, easy processing, weather and corrosion resistance and aesthetic appeal, has found widespread application across multiple industries, meeting both functional requirements (such as reflection, heat dissipation, and protection) and decorative appeal.

1. Lamp reflectors: The core demand is "efficient light collection/reflection, enhancing lighting efficiency."

Mirror aluminum sheet is the core material for lamp reflector systems. Its reflectivity directly determines lighting efficiency, making it particularly suitable for applications requiring high light efficiency.

- Applications:

Home lighting, commercial lighting, industrial lighting, and specialty lighting (such as stage lights and medical surgical lights).

- Key Advantages:

Reflectivity reaches 85%-95% (some high-precision mirror aluminum sheet can reach 98%), far exceeding that of ordinary aluminum sheet/plastic, reducing light loss.

High-temperature resistance (150-300°C, depending on the coating), compatible with heat-generating light sources such as LEDs and halogen lamps.

Easily stamped into complex curved surfaces (such as paraboloids and arcs), tailored to the light collection requirements of various lamps.

2. Solar reflectors: The core requirement is "efficient light concentration to improve energy conversion efficiency."

In solar energy utilization systems, mirror aluminum sheets are a key material for the "light concentration process" and must withstand harsh outdoor environments (high temperatures, UV rays, wind and rain) for extended periods.

- Applications:

Trough solar thermal power generation, solar water heaters, and integrated photovoltaic (PVT) systems.

- Core Advantages:

High mirror reflectivity (≥90%) precisely focuses sunlight onto the absorber tube/photovoltaic panel, improving energy collection efficiency.

Strong weather resistance (surface oxidation/coating treatment) resists UV aging and rain corrosion, with an outdoor service life of 10-15 years.

Lightweight (density of only 2.7g/cm³, approximately one-third that of stainless steel), reducing support load and system installation costs.

3. Construction: The core demand is "aesthetic decoration + functional protection (thermal insulation, weather resistance)."

Mirrored aluminum sheets are used in two architectural applications: exterior walls/roofs and interior decoration, combining aesthetics with practicality.

- Application Scenario 1: Building Exterior Walls/Roofs

Key Advantages: Strong metallic luster, capable of creating mirrored, brushed, and iridescent effects, enhancing building recognition; lightweight (80% lighter than stone, 50% lighter than glass), reducing wall load; surface coatings (such as fluorocarbon coatings) are resistant to acid rain and UV rays, with a service life of over 20 years.

- Application Scenario 2: Interior Decoration

Core Advantages: The mirrored effect can visually expand a space (e.g., making a small apartment appear larger). It can be easily processed into curved and custom shapes, complementing modern minimalist/light luxury styles. The surface is smooth, easy to clean, and resistant to oil and scratches.

4. Automotive Decoration: Core Requirements: "Lightweight + Aesthetics + Scratch Resistance"

The automotive industry places extremely high demands on materials for weight reduction, energy efficiency, and aesthetics, making mirrored aluminum sheets a perfect fit. They are used in both interior and exterior applications.

Application Scenario 1: Automotive Interior

Key Advantages: Lightweight (40% lighter than traditional chrome-plated parts), in line with the automotive trend of reducing weight and fuel consumption; a refined metallic luster elevates the interior's quality; and a wear-resistant surface coating (such as PU coating) resists fingerprints and is easy to clean.

Application Scenario 2: Automotive Exterior

Core Advantages: Strong weather resistance (withstands temperatures ranging from -40°C to 80°C), acid rain resistance, and stone impact resistance. The mirror finish enhances the vehicle's refinement and is easier to form than stainless steel.

5. Furniture and Appliances: Core Requirements: "Aesthetics, Durability, and Easy Cleaning."

The surface materials used in furniture and appliances must balance aesthetics and practicality. Mirrored aluminum sheet can replace glass and stainless steel, reducing costs and improving safety.

- Application Scenario 1: Furniture Industry

Core Advantages: Lighter than glass (less prone to shattering, suitable for children's rooms), more moisture-resistant than wood (suitable for bathrooms and kitchens); customizable colors (such as champagne gold and rose gold) to suit different home styles; smooth surface that can be cleaned with a damp cloth.

- Application Scenario 2: Home Appliance Industry

Core Advantages: High-temperature resistance (suitable for ovens and microwaves), oil and stain resistance (suitable for range hoods and stoves), and easy cleaning; the metallic finish elevates appliances, distinguishing them from ordinary plastic housings.

6. Electronics and Electrical Appliances: Core Demands: "Lightweight + Heat Dissipation + Decorative Features"

In addition to home appliances, the demand for thinness and quality in consumer electronics (mobile phones, computers, headphones) has made mirrored aluminum sheet a key material.

- Applications: Mobile phone cases/midframes, laptop cases, headphone cases, smart wearable devices (such as watch cases).

- Core Advantages:

Ultra-thin (processable down to 0.1-0.5mm) and lightweight, suitable for thin and light electronic devices;

Excellent thermal conductivity (over 10 times higher than plastic), assisting in heat dissipation (e.g., laptop cases);

The surface can be anodized and mirrored to create matte or colorful mirror effects, enhancing product recognition.

7. Signage: The core requirements are "eye-catching reflectivity + outdoor weather resistance."

Outdoor advertising and signage require "eye-catching during the day and reflective at night." Mirrored aluminum's high reflectivity and weather resistance are a perfect fit.

- Applications:

Outdoor advertising light boxes, brand logos, road signs, shopping mall signage.

- Key Advantages:

During the day, the metallic luster attracts attention. At night, combined with lighting (such as the light box's internal lighting), it creates "secondary reflection" for enhanced visibility.

Strong weather resistance (UV and rain resistance) ensures an outdoor lifespan of 5-8 years, eliminating the need for frequent replacement.

Easy to cut and bend, allowing for any shape (such as round or custom-shaped logos).

8. Packaging: The core requirements are "upgraded quality + protection (corrosion resistance, drop resistance)."

High-end gift packaging, cosmetics, jewelry, and health supplements require both aesthetic appeal and protection. Mirrored aluminum sheet is a preferred alternative to glass and plastic.

- Applications:

Cosmetic packaging, health product gift boxes, high-end wine boxes, and luxury goods packaging.

- Core Advantages:

Strong metallic texture enhances the product's "high-end" attributes (e.g., mirrored aluminum cans for skincare products, distinguishing them from ordinary plastic bottles);

Excellent sealing and corrosion resistance protect contents (such as essential oils and creams) from moisture and deterioration;

Can be printed and embossed to create custom designs (such as brand logos and patterns) for enhanced brand recognition.

9. Industrial Equipment: Core requirements are "oil resistance, high temperature resistance, and easy cleaning."

The surface panels of industrial machine tools, medical equipment, and laboratory instruments must withstand harsh environments (such as oil, high temperatures, and chemical corrosion), making mirrored aluminum sheets highly adaptable.

- Applications:

Machine tool operating panels, medical diagnostic instrument housings, and laboratory reactor panels.

- Key Advantages:

Smooth, oil-resistant surface that can be wiped clean with alcohol or detergent for easy cleaning;

High-temperature resistance (some models can withstand temperatures exceeding 300°C) and chemical resistance (such as acid and alkali resistance) make it suitable for industrial and medical applications;

High mechanical strength, impact resistance, and deformation resistance ensure long-term stability.

Core Advantages of Mirrored Aluminum Sheets

All of the aforementioned application areas revolve around the five core advantages of mirrored aluminum sheets, which are key to their replacement for glass, stainless steel, and plastic:

- High Reflectivity:

85%-98% reflectivity, suitable for reflective applications (lighting, solar panels, signage);

- Lightweight:

Density is only 2.7g/cm³, far lower than stainless steel (7.9g/cm³) and glass (2.5g/cm³ and fragile), reducing installation and transportation costs;

- Easy to Process:

Can be stamped, cut, bent, and welded to create curved and custom-shaped structures (such as lamp reflectors and building curtain walls);

- Weather and Corrosion Resistance:

Surface oxidation/coating treatments provide resistance to UV rays, acid rain, and oil stains, making it suitable for outdoor and harsh environments;

- Aesthetics and Cost-Effectiveness:

A strong metallic luster enhances product quality, while costing less than stainless steel and glass, achieving both aesthetics and affordability.

It is precisely these advantages that have upgraded mirror aluminum sheets from "single decorative materials" to "functional + decorative integrated materials", penetrating into all scenarios from people's livelihood (furniture and home appliances) to industry (solar energy, machine tools).

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531