6082 vs 6061 Aluminum

6061 vs 6082 aluminum alloys are important 6000 series aluminum alloy materials, with their own unique performance and application areas.

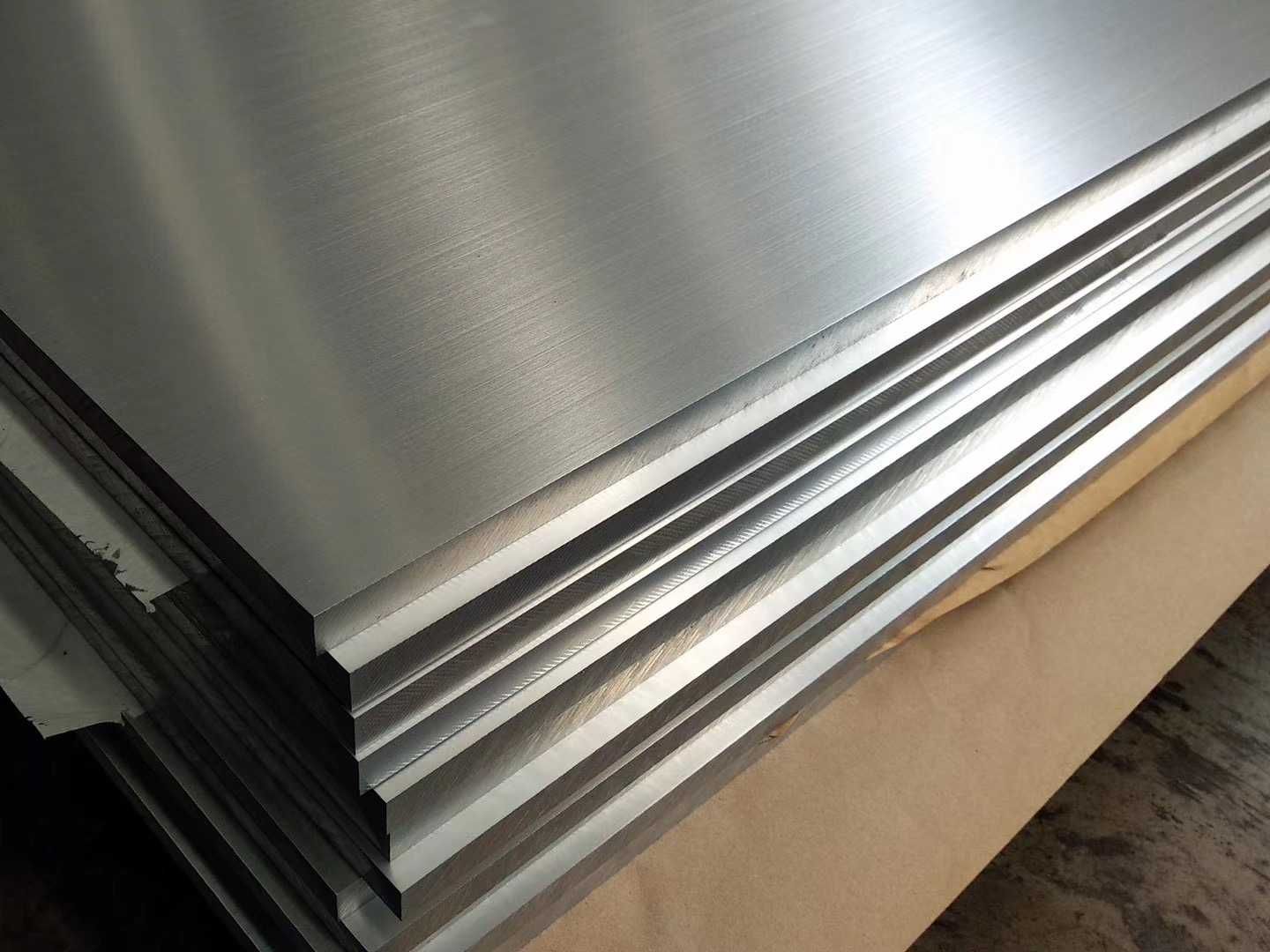

6061 vs 6082 aluminum alloys are important 6000 series aluminum alloy materials, with their own unique performance and application areas. 6000 series aluminum alloy is a kind of magnesium and silicon as the main elements of the aluminum alloy, has excellent plasticity and workability, at the same time, has good corrosion resistance. 6061 and 6082 aluminum alloys are only in the composition of a slightly different, so their performance and application areas are different. Therefore, their performance and application areas are also different.

6061 vs 6082 aluminum are two commonly used aluminum alloys, and there are some similarities and differences between them.

Similarities:

Both belong to the 6000 series of aluminum alloys, so both have good plasticity and workability.

Both have good corrosion resistance and can be used for a long time in some environments.

Both can be surface treated by anodizing or spraying to improve corrosion resistance and aesthetics.

Differences of 6082 vs 6061 aluminum:

Different composition:

The composition of 6061 aluminum sheet alloy is more focused on the content of magnesium and silicon elements than 6082 aluminum alloy, while 6082 aluminum alloy is more focused on the content of manganese and chromium elements. This difference in composition leads to differences in mechanical properties and heat treatment characteristics.

Mechanical properties are different:

The mechanical properties of 6061 aluminum alloy is relatively excellent, with high strength and good fatigue resistance, suitable for the manufacture of structural parts need to withstand large loads. The strength and hardness of 6082 aluminum alloy is relatively low, but the toughness is better, suitable for the manufacture of structural parts that need to withstand shock and vibration.

Heat treatment characteristics are different:

6061 aluminum alloy has good heat treatment characteristics, can improve its mechanical properties through heat treatment. The heat treatment characteristics of 6082 aluminum sheet alloy are relatively poor, and the improvement of its mechanical properties by heat treatment is small.

Different applications: Because of its excellent mechanical properties, 6061 aluminum alloy is widely used in construction, aviation, automotive and other fields. While 6082 aluminum alloy is more often used in ships, railroads, electric power and other fields.

In general, 6082 vs 6061 aluminum alloy have differences in the aspects of composition, mechanical properties, heat treatment characteristics and uses and others, so in the choice of use should be based on specific needs to choose the right material.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531