Aluminium 1100 VS 6061

1060 aluminum alloy and 6061 aluminum alloy are two commonly used aluminum alloy materials with different compositions and properties for different applications.

1060 aluminum alloy and 6061 aluminum alloy are two commonly used aluminum alloy materials with different compositions and properties for different applications.

The following is a detailed comparison of these two aluminum alloys, including composition, properties, applications, advantages and disadvantages.

1. Composition

- 1060 aluminum alloy belongs to the pure aluminum series, with an aluminum content of more than 99.6%, and the main alloying element is aluminum, containing almost no other alloying elements.

- 6061 Aluminum Alloy:

- 6061 aluminum alloy belongs to aluminum-magnesium-silicon alloy, the main alloying elements are magnesium (about 0.8% to 1.2%) and silicon (about 0.4% to 0.8%), and a small amount of copper, manganese, chromium and zinc and other elements.

2. Characteristics

- 1060 Aluminum Alloy:

- Advantages: good electrical, thermal and corrosion resistance, good formability and weldability.

- Disadvantages: Relatively low strength, suitable for applications that do not require high strength.

- 6061 Aluminum Alloy:

- Advantages: excellent mechanical properties, high strength, good toughness and corrosion resistance, easy to process and weld, suitable for heat treatment.

- Disadvantages: Compared to 1060 aluminum alloy, 6061 aluminum has slightly inferior electrical and thermal conductivity.

3. Application

- 1060 Aluminum Alloy:

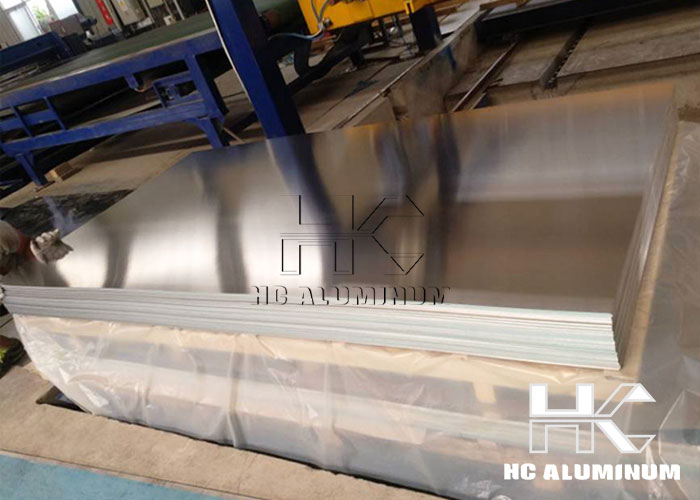

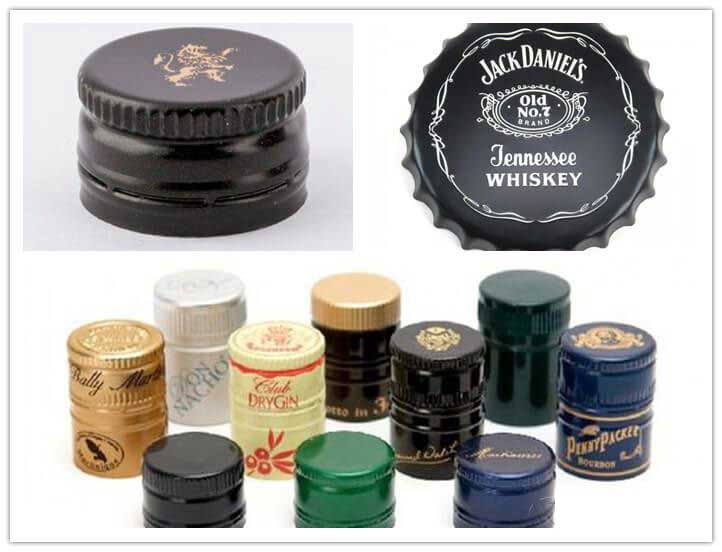

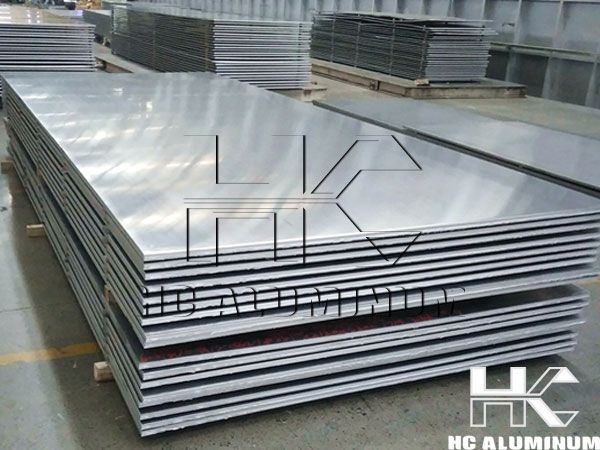

- Commonly used in the manufacture of electrical equipment, chemical equipment, food processing, cosmetic packaging, aluminum foil, aluminum plate and other products that do not require high strength. Suitable for products that require good electrical conductivity and thermal conductivity.

- Suitable for applications requiring good electrical and thermal conductivity, such as cable conductors.

- 6061 Aluminum Alloy:

- Widely used in aerospace, automotive, construction, mechanical engineering, etc. Commonly used in the manufacture of high-strength structural components, such as frames, tubes, car bodies and parts.

- Suitable for applications requiring high strength and corrosion resistance, such as ships, bridges and high pressure vessels.

4. Summary

- 1060 Aluminum Alloy:

- Advantages: high electrical and thermal conductivity, good corrosion resistance, good formability.

- Disadvantages: low strength, not suitable for applications subjected to high mechanical loads.

- 6061 Aluminum Alloy:

- Advantages: high strength, good toughness, excellent corrosion resistance, heat treatable, easy to machine, good weldability. Disadvantages: electrical and thermal conductivity.

- Disadvantages: relatively low electrical and thermal conductivity, not suitable for applications requiring very high electrical conductivity.

1060 and 6061 aluminum alloys each have unique advantages and areas of application. 1060 aluminum alloy is suitable for applications requiring good electrical conductivity and corrosion resistance, while 6061 aluminum alloy is suitable for use in structural components requiring high strength and good weldability. When selecting an aluminum alloy material, the choice should be based on the specific application needs and performance requirements.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531