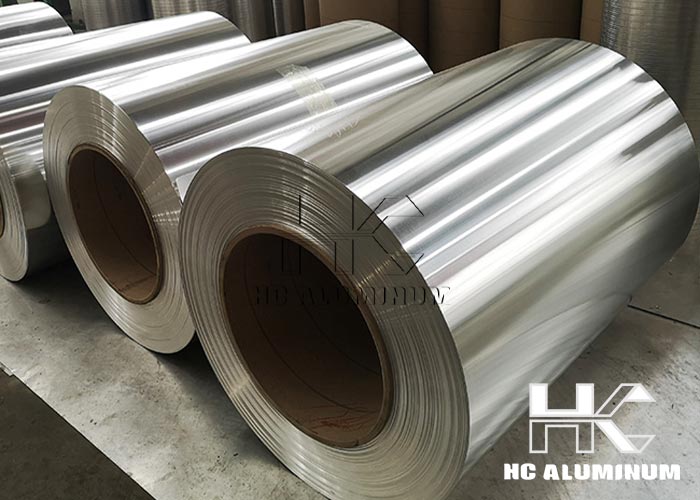

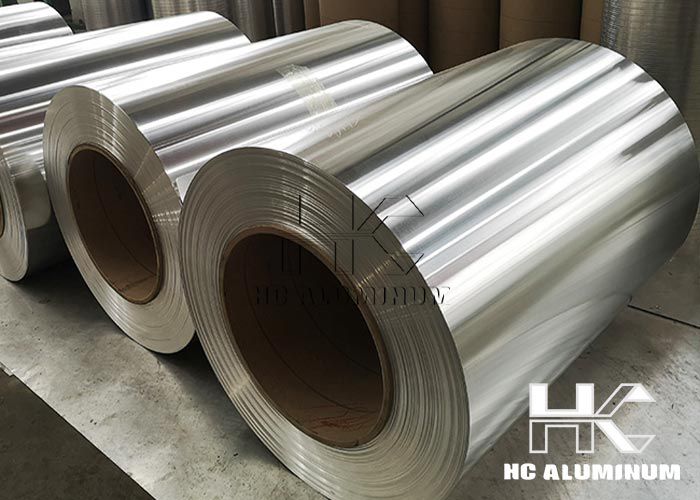

Aluminum Coil Manufacturers In China

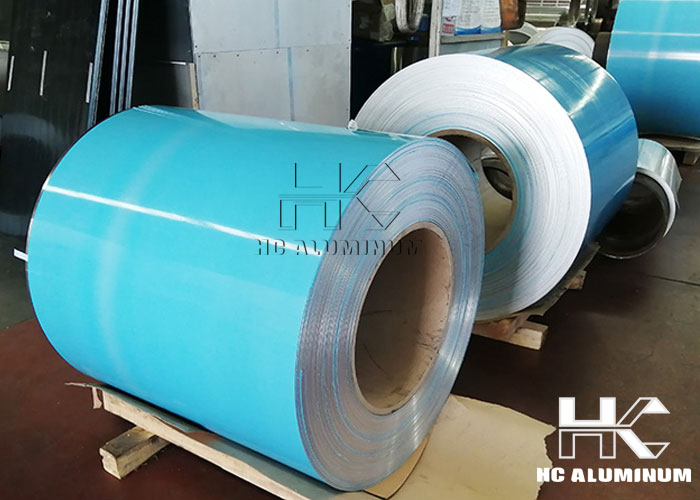

Aluminum coil manufacturers in China usually use advanced rolling equipment and processes to produce 1000, 3000, 5000 and 6000 series aluminum coils.

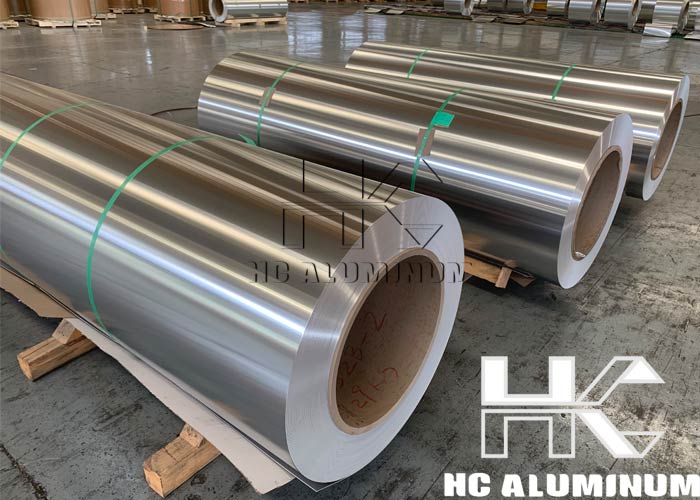

Aluminum coil manufacturers in China usually use advanced rolling equipment and processes to produce 1000, 3000, 5000 and 6000 series aluminum coils. The production process of aluminum coil generally includes raw material selection, melting, casting, hot rolling, cold rolling, drawing and annealing. Common specifications of the produced aluminum coil product include thickness, width and coil weight.

- Thickness: usually between 0.2mm and 6mm.

- Width: usually between 100mm and 2000mm.

- Coil weight: usually between 1 ton and 10 tons according to customer demand.

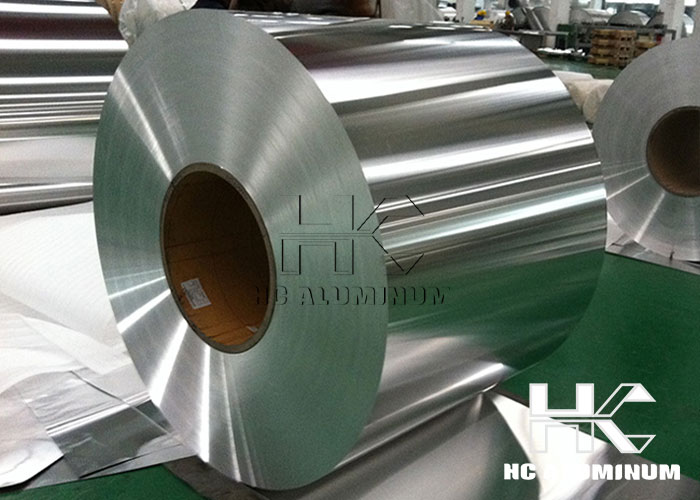

1000 series aluminum coil is generally pure aluminum, with good thermal conductivity and corrosion resistance, 1050 aluminum coil and 1060 aluminum coil are commonly used in the manufacture of food packaging, wire and cable, construction materials.

3000 series aluminum coil is mainly manganese element alloy aluminum, with good strength and corrosion resistance, 3003 aluminum coil is commonly used in shipbuilding, automobile manufacturing, aerospace and other fields.

5000 series aluminum coil for magnesium alloy aluminum, has excellent strength and corrosion resistance, 5052 aluminum coil is commonly used in aerospace, automotive manufacturing, construction materials.

6000 series aluminum coil is magnesium-silicon alloy aluminum, with excellent strength and heat resistance, 6061 aluminum coil is commonly used in automobile body panels, aluminum alloy doors and windows, pressure vessels and other fields.

Characteristics of aluminum coil produced by manufacturer in China:

- Lightweight: aluminum coil has low density, specific gravity is about 2.7g/cm³, it is a lightweight metal material.

- Corrosion resistance: Aluminum has good corrosion resistance and can keep the surface brightness for a long time in different environments.

- Thermal Conductivity: Aluminum has good thermal conductivity and is suitable for application scenarios that require heat dissipation.

- Processability: Aluminum coils are easy to process into various shapes, which can be processed by cutting, bending, welding and other processes.

Application scenario of aluminum coil:

- Construction field: used for manufacturing aluminum alloy doors and windows, aluminum alloy curtain walls, roofing sheets, etc.

- Packaging: used in food packaging, pharmaceutical packaging, cosmetic packaging, etc.

- Transportation field: used in automobile manufacturing, shipbuilding, aerospace and so on.

- Electrical and electronic field: used for wires and cables, electronic product shells, radiators and so on.

Overall, aluminum coil has the characteristics of light weight, corrosion resistance, good thermal conductivity, etc. It is suitable for applications in many fields and is a widely used metal material. Different series of aluminum coils have different specifications and characteristics, customers can choose the right product for different applications according to specific needs.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531