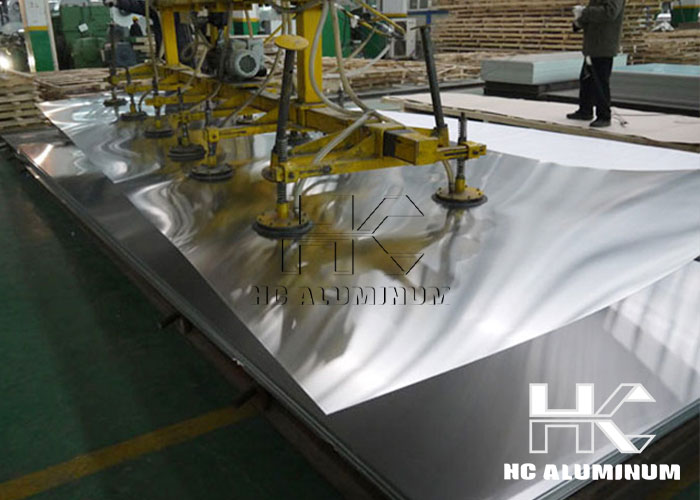

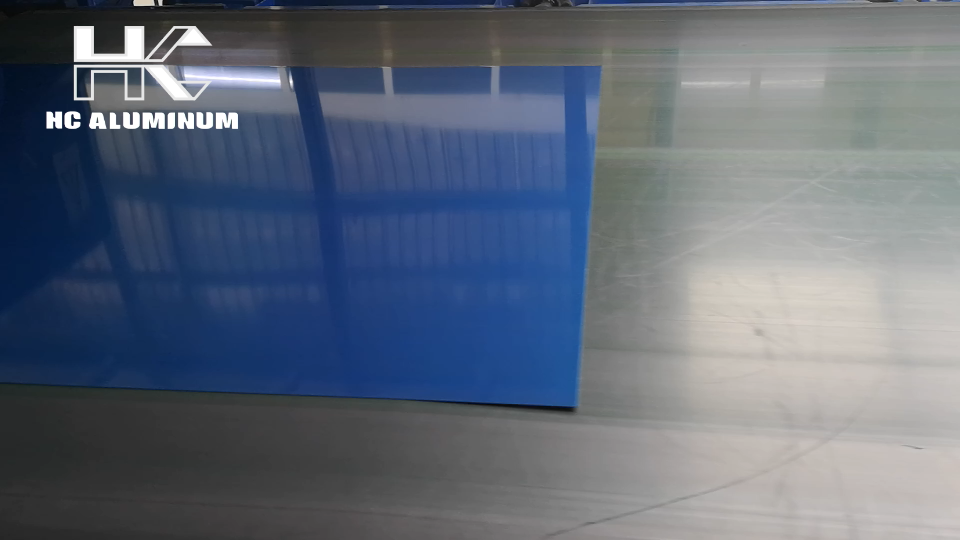

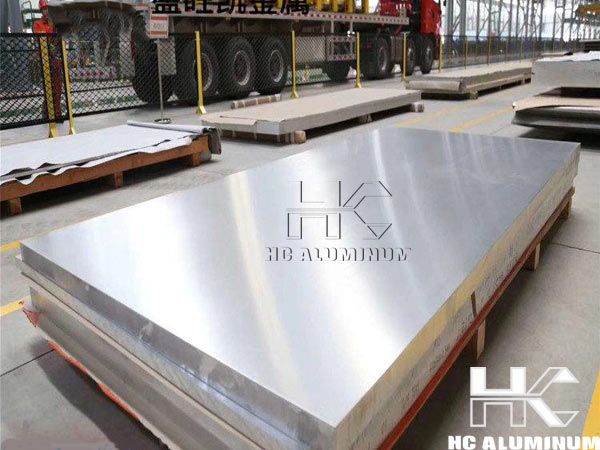

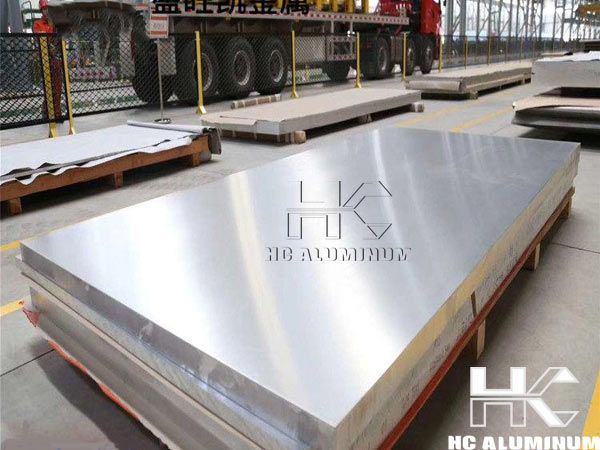

Anodized Aluminum Sheet

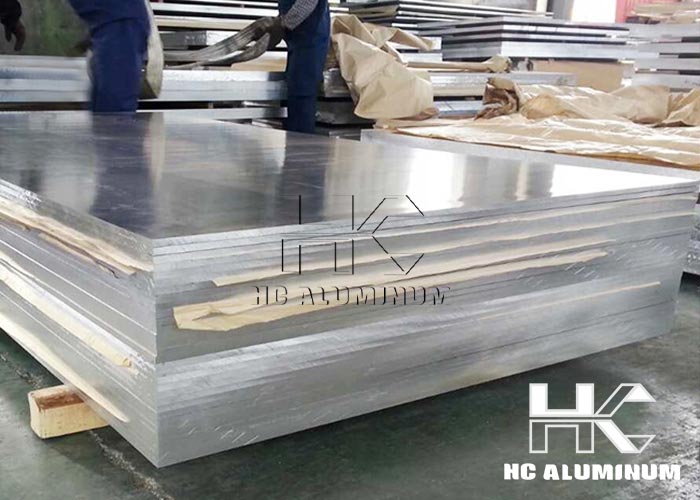

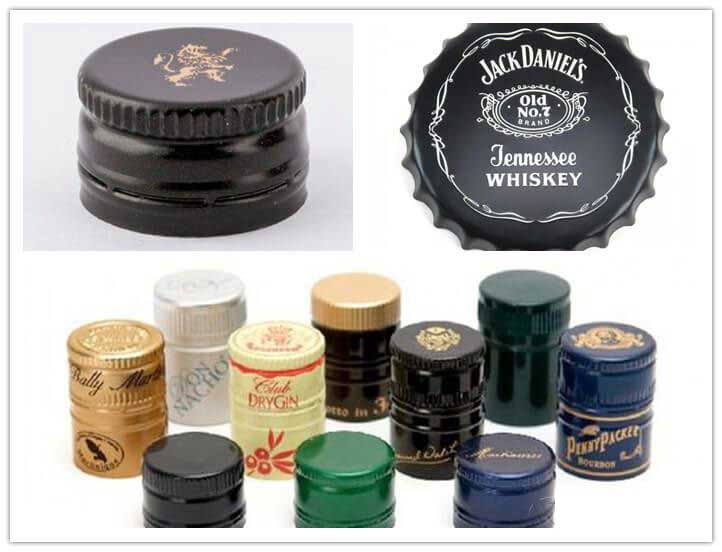

The usefulness of anodized aluminum sheet is reflected in all aspects of life for its good performance, lightweight and beautiful appearance.

The usefulness of anodized aluminum sheet is reflected in all aspects of life for its good performance, lightweight and beautiful appearance. The consumption of anodized aluminium sheet is increasing in recent years, and we HC Aluminum got more experience on anodised aluminum sheet processing and export. What are the types and processes of anodized aluminium sheets oxidation? Please listen to the editor for your analysis.

1, The general principle of the formation of oxide film of anodized aluminum sheet:

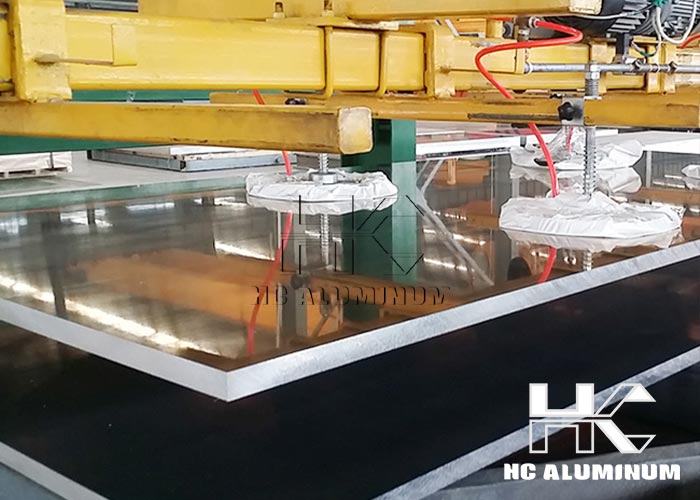

The process of using the aluminum plate as the anode to place it in the electrolyte solution and using the electrolytic effect to make the surface form an aluminum oxide film is called anodizing treatment of the aluminum plate. The cathode in the device is a material with high chemical stability in the electrolytic solution, such as lead, stainless steel, aluminum, etc. The principle of aluminum anodization is essentially the principle of water electrolysis. When the current is passed, on the cathode, hydrogen gas is released; on the anode, the separated oxygen is not only molecular oxygen, but also contains atomic oxygen (O) and ionic oxygen, usually expressed as molecular oxygen in the reaction. The aluminum used as the anode is oxidized by the oxygen separated on it to form an anhydrous aluminum oxide film. The generated oxygen does not all have the effect of aluminum, but a part of it is separated in a gaseous form.

2, Selection of oxidizing electrolytic solution for anodized aluminum plate:

A prerequisite for the growth of the anodic oxide film is that the electrolyte should have a dissolving effect on the oxide film. However, this does not mean that anodizing can generate oxide films or that the properties of the oxide films produced are the same in all electrolytes with a dissolution effect.

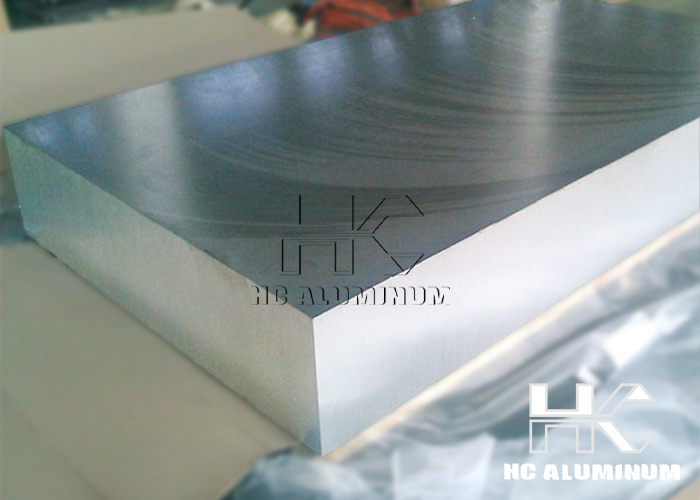

3, Varieties of anodized aluminum sheet oxidation:

Anodizing is divided into: direct current anodizing, alternating current anodizing, and pulse current anodizing. According to the electrolyte, it is divided into: sulfuric acid, oxalic acid, chromic acid, mixed acid and natural color anodizing with sulfo-organic acid as the main solution. According to the properties of the film layer, it is divided into: general film, hard film (thick film), porcelain film, bright light modification layer, barrier layer with semiconductor effect, etc. Among the anodizing methods and process conditions for aluminum and aluminum alloys, the application of direct current sulfuric acid anodizing method is the most common.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531