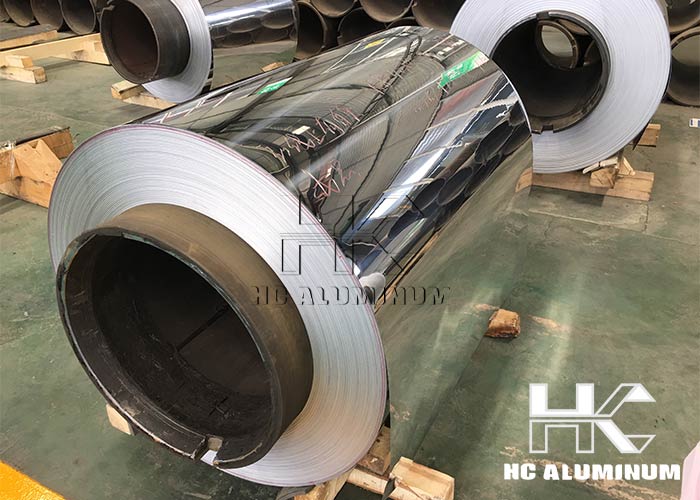

High Polished Aluminum Sheets

In modern industrial design and manufacturing, high polished aluminum sheets are favored for their excellent surface characteristics and reflective properties.

In modern industrial design and manufacturing, high polished aluminum sheets are favored for their excellent surface characteristics and reflective properties. This material is not only aesthetically pleasing, but also has excellent functionality and is used in a wide range of industries.

Highly polished aluminium sheet is an aluminum alloy sheet that has been specially treated to achieve an extremely high gloss and smooth surface. Tiny surface irregularities are removed by chemical or electrolytic polishing, allowing light to be reflected almost completely, resulting in an extremely high mirror finish. The surface finish usually reaches several nanometers, which gives it a mirror-like effect, as well as good corrosion resistance, wear resistance and anti-aging properties. Mainly, the mirror polished aluminum sheet is 1070 h18 with thickness of 0.2-1mm and width of 10-1250mm.

Reflectivity performance

High polished aluminum sheet can have a total light reflectivity of 95% to 98%, indicating that it can reflect light very efficiently, making it ideal for use as a reflector for lighting fixtures. For application scenarios that require efficient use of light sources, such as reflective materials in solar collectors or reflector panels for high-end lamps, such reflectivity can greatly enhance energy utilization and lighting efficiency.

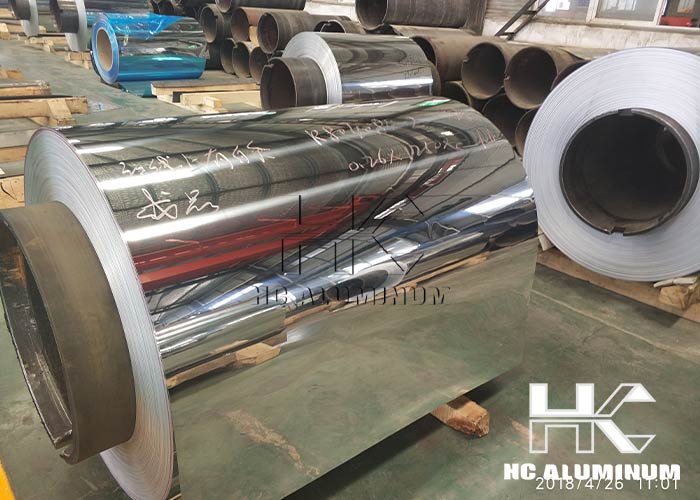

Production Process

The production of highly polished aluminium sheets is a complex and delicate process. First, the raw material is mechanically polished to initially flatten the surface; next, the surface quality is further improved using triac chemical polishing or electrochemical polishing. Electrolytic polishing utilizes the principle of electrochemical anodic dissolution to form a uniform oxide film on the surface of the metal at a specific current density, and regulates the smoothness and brightness of the final surface with the help of different thicknesses of the film. It is worth noting that in order to reduce environmental pollution, the current technology trend favors the use of nitric acid-free, chromic anhydride-free environmentally friendly polishing fluid formulations.

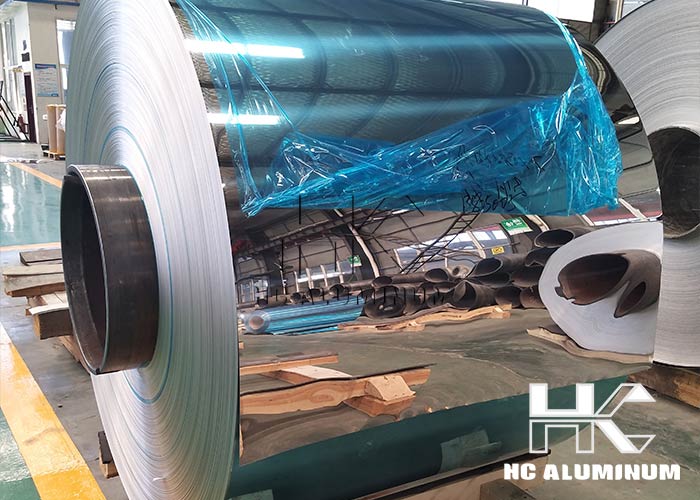

Areas of application

High polished aluminum sheets are used in a wide range of applications. From architectural decoration to the shell production of electronic products, to automotive interior and exterior parts and signage and other fields have its figure. Especially in occasions with high requirements for optical performance, such as lighting reflective panels and lamp decoration, solar collector reflective materials, etc., it has become an indispensable component due to its excellent reflective properties. In addition, with the enhancement of consumers' pursuit of appearance quality, many consumer electronics products have also begun to use a large number of highly polished aluminum mirror sheet as the appearance of materials, in order to enhance the sense of technology and fashion products.

In short, with its unique physical properties and processing advantages, high polished aluminum sheet plays an important role in many industries. Whether it is to enhance the visual appeal of the product or improve the functional performance, it has shown an irreplaceable value. In the future, with the continuous progress of surface treatment technology, we have reason to believe that high polished aluminum plate will shine in more innovative applications.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531