-

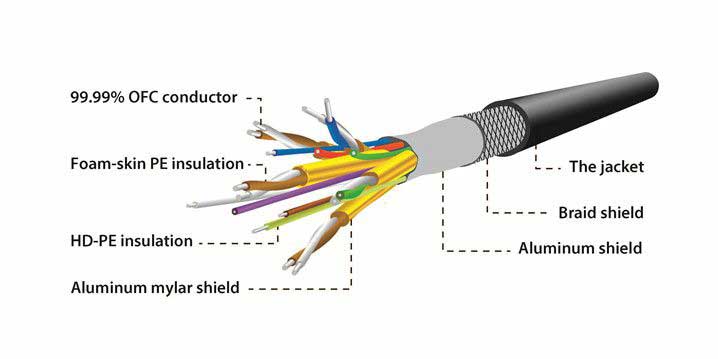

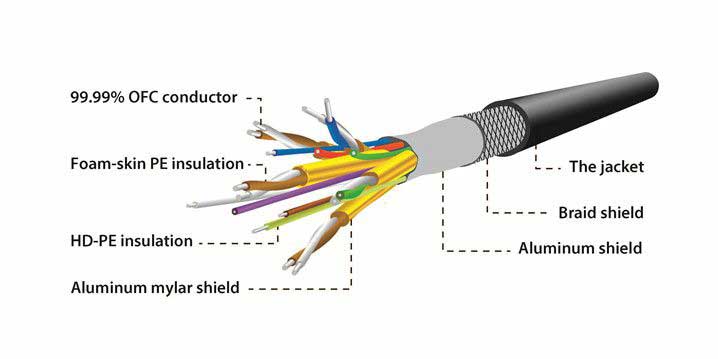

In electrical cables, aluminium foil is an essential component providing long-term protection. It is used to wrap the innermost conductor material.

In electrical cables, aluminium foil is an essential component providing long-term protection. It also insulates against magnetic and radio frequency emissions. Used in fibre-optic cables, aluminium foil acts as a ‘tracer’ to enable testing of the integrity of cable links.

Cable Wrapping Material-Aluminum Foil | |||||

Alloy | Temper | Thickness(mm) | Width(mm) | Length (mm) | Application |

1145, 8011, 1200 | O | 0.15~0.20 | 15mm~500 | 2050 | telecommunication cable |

Film: EMAA/EAA 0.05mm tolerance +/-0.005mm Both sides laminated and one side laminated | |||||

Remark: special specifications can be produced accordingly to your requirement. |

Technical Data of Aluminum Alloy for Armoured Cable Wrap

Heat resistance (N/cm) | ≥17.5 |

Peeling strength (N/cm) | ≥6.13 |

Water resistance (68+/-1C, 168H) | ≥6.13 |

Tensile Strength (Mpa) | ≥54 |

Elongation rate % | ≥15 |

Anticorrosion | (0.1mol/L, NaoH, 480h) ≥7 |

Dielectric strength 1kVd.c.1.min ELE (single side laminated tape) | No discharged |

Dielectric strength 1kVd.c.1.min ELE (single side laminated tape) | No discharged |