-

1060 aluminum strip belongs to pure aluminum, mainly used for transformer winding. It is of cheap price, high conductivity, soft texture and smooth surface. Learn more here!

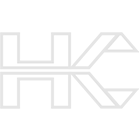

Why We Use Aluminum Strip for Transformer

The electrical and thermal conductivity of aluminum is only lower than copper. Since the price of copper is much higher than that of aluminum, the most commonly used material for transformer is aluminum strip/foil/sheet.

Characteristics of 1060 Aluminum Strip for Transformer

1060(O) Aluminum strip is mainly used as high- and low-voltage winding for dry-type transformers. It has high conductivity, soft texture, smooth surface and no burr. It is an ideal material for the production of dry-type transformers and a key raw material for the manufacture of transformer winding.

Major brand | A1060(O)/A1050(O) | ||||

Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

Tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

Tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

Burr and Collapse | |||||

The width of aluminum belt | Burr’s height | Collapsed side’s height | |||

<0.2 | 0.01 | ≥0.05-0.1 | |||

0.2-1.0 | 0.015 | ||||

1.1-1.5 | 0.02 | ||||

>1.6 | 0.03 | ||||

Mechanical Property | |||||

Major brand | A1060(O)/A1050(O) | ||||

Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

Tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

Tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

Burr and Collapse | |||||

The width of aluminum belt | Burr’s height | Collapsed side’s height | |||

<0.2 | 0.01 | ≥0.05-0.1 | |||

0.2-1.0 | 0.015 | ||||

1.1-1.5 | 0.02 | ||||

>1.6 | 0.03 | ||||

Mechanical Property | |||||

U.T.S: 60-95N/mm2 | Elongation: >25% | ||||

Density in 20℃ :2.703kg/dm3 | Max.resistance in 20℃:≤0.02825Ωmm2/m |