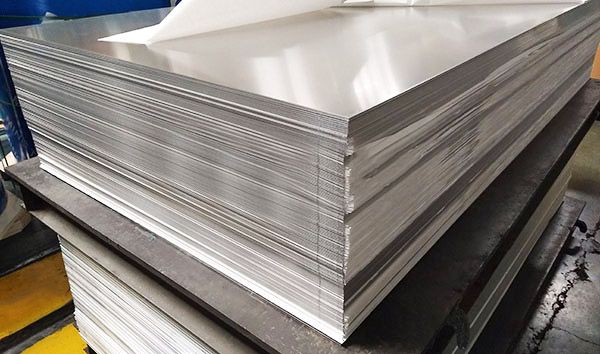

3105 H14 Aluminum Sheets

3105 H14 aluminum sheet is a typical aluminum-manganese (Al-Mn) rust-resistant aluminum alloy through a cold work hardening process (H14 temper).

3105 H14 aluminum sheet is a typical aluminum-manganese (Al-Mn) rust-resistant aluminum alloy. Through a cold work hardening process (H14 temper), it achieves moderate strength and excellent overall performance. It is widely used in applications requiring high corrosion resistance, formability and lightweighting.

Alloy Composition:

3105 aluminum alloy belongs to the Al-Mn aluminum-manganese alloy family. Its primary components are aluminum (Al) and manganese (Mn). It also contains a small amount of copper (Cu, ≤0.2%) to enhance tensile strength without compromising corrosion resistance.

Processing Tempering:

H14 indicates a temperature achieved through work hardening and partial annealing, combining strength and hardness while maintaining good processability.

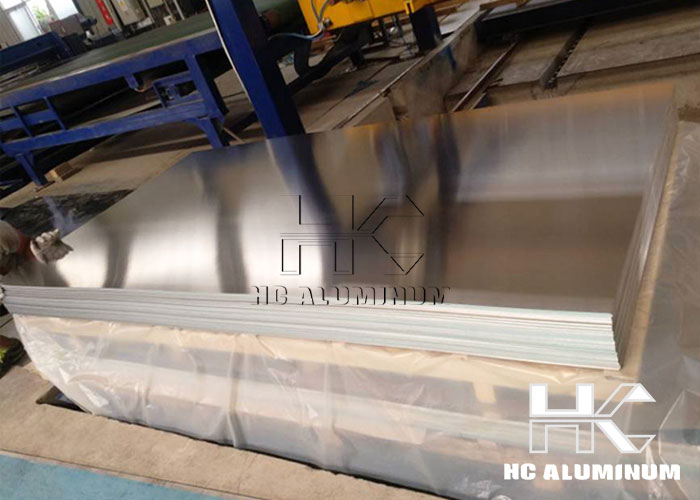

Parameters of 3105 h14 aluminum sheets

Thickness Range: 0.1-500mm, meeting processing requirements for various shapes and sizes.

Width Range: 100-2650mm, adapting to various widths and applications.

Length Range: 500-16,000mm, supporting customized production.

Performance Advantages of aluminium sheet 3105 h14:

- Excellent Corrosion Resistance

A dense Al₂O₃ oxide film naturally forms on the surface, providing excellent resistance to atmospheric air, seawater, and dilute acid environments, making it particularly suitable for humid or corrosive environments (such as building roofs and automobile fuel tanks). The addition of manganese further enhances pitting corrosion resistance, resulting in corrosion resistance superior to that of 3003 aluminum alloy.

- Excellent Machinability and Weldability

Formability: The annealed state allows for deep drawing to create complex parts (such as beverage cans and lithium battery casings). The H14 state is suitable for moderate bending and stamping processes.

Weldability: Compatible with argon arc welding (TIG) and metal inert gas welding (MIG), achieving weld strength close to that of the parent metal and low porosity.

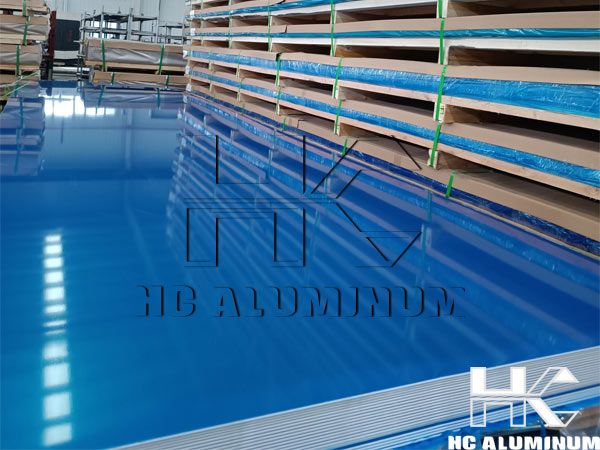

Surface Treatment: Anodizing results in uniform color and strong paint adhesion, making it a popular choice for architectural decoration.

Medium Strength and Conductivity: Its tensile strength lies between pure aluminum (60-100 MPa) and 6061 alloy (≥290 MPa), meeting the requirements of most structural parts. Its conductivity is approximately 41% IACS (International Annealed Copper Standard), making it suitable for applications requiring high conductivity (such as electrical equipment housings).

Applications of 3105 h14 aluminum sheets:

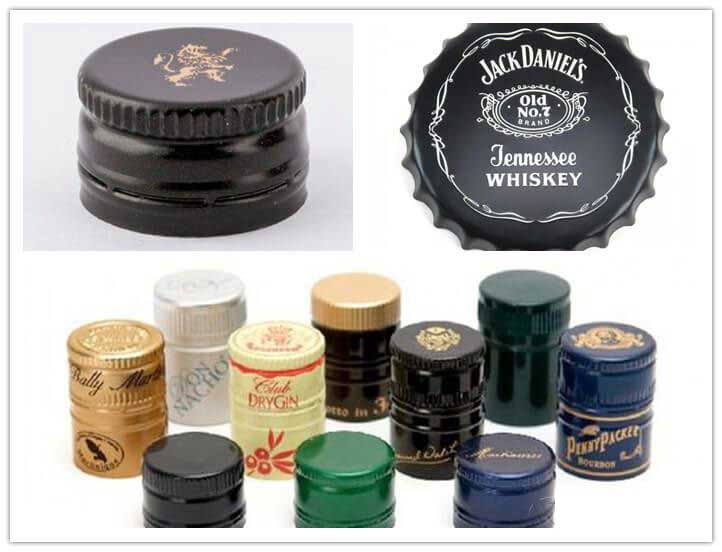

- Packaging Industry:

Bottle caps (for packaging of alcoholic beverages, cosmetics, and pharmaceuticals).

Sheet metal forming parts such as tea cans, cake trays, and candle cups.

- Architectural Decoration:

Blinds, color-coated aluminum coils, gutters, and downspouts.

Room dividers, baffles, and movable roof panels.

It provides both structural strength and long-term resistance to environmental corrosion. Anodizing allows for a variety of colors, enhancing aesthetics.

- Electronic and Electrical Appliances:

Mobile phone lithium battery cases, radiators, lamp holders, and other components requiring high corrosion resistance and formability.

- Automotive Lightweighting:

Fuel tanks, body panels, interior trim, and other applications utilize its low density and corrosion resistance to reduce vehicle weight and extend service life.

- Other Applications:

Products requiring corrosion resistance and strength, such as signs and hoods.

3105 H14 aluminum sheet alloy demonstrates outstanding corrosion resistance and formability, making it particularly suitable for applications requiring lightweighting and long-term durability. This aluminum alloy can undergo surface treatments such as anodizing to further enhance its corrosion resistance and extend its service life.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531