Aluminium Alloy Sheet

Aluminium alloy sheet has been widely used in many industrial fields due to its excellent properties such as light weight, corrosion resistance, good electrical and thermal conductivity.

Aluminium alloy sheet has been widely used in many industrial fields due to its excellent properties such as light weight, corrosion resistance, good electrical and thermal conductivity. As one of the important materials, aluminum alloy sheet not only occupies an important position in aerospace and automobile manufacturing, but also plays an important role in building decoration and packaging materials.

Common aluminium alloy sheet grades:

1. 1000 Series

- Pure aluminum sheet, such as 1050, 1060, 1070, 1100, etc., which is characterized by very high plasticity and corrosion resistance, but lower strength, suitable for less demanding and need good formability.

2. 3000 Series

- Aluminum-manganese alloy sheets, such as 3003, 3004, 3105, etc., which are commonly used for tanks, heat sinks, etc., due to the addition of manganese elements, which gives them better rust resistance.

3. 5000 Series

- Aluminum-magnesium alloys, such as 5005, 5052, 5083, 5086, 5754, etc. These aluminum sheet alloys have high tensile strength and excellent corrosion resistance, and are suitable for use in the field of ships, vehicle fuel tanks and aircraft fuel tanks.

4. 6000 Series

- Aluminum-magnesium-silicon alloy sheets, such as 6061, 6063, 6082, etc. By adding magnesium and silicon elements, this series of aluminum alloy sheet has better mechanical properties, especially welding performance, widely used in building structures, bridges and various machine parts.

5. 7000 Series

- Aluminum-zinc-magnesium-copper alloy sheets, such as 7075, etc. These alloys have the highest strength of all aluminum alloys, with good mechanical properties and fatigue strength, and are mainly used for aircraft structural parts and high-strength components.

Performance characteristics of aluminium alloy sheet:

- Lightweight and High Strength: Compared to steel, it is lighter in weight for the same volume, but its strength can reach or even exceed that of some steel grades, which is especially suitable for weight-sensitive application scenarios.

- Corrosion resistance: Naturally formed oxide film can effectively prevent the external environment from eroding the metal surface.

- Good processing performance: easy to cut, bend, stamping and other forms of processing treatment.

- Electrical and thermal conductivity: good electrical and thermal conductivity makes it irreplaceable in the electronic and electrical industries.

Application areas of aluminium alloy sheet:

- Transportation: aircraft wings, body panels, etc., using its lightweight advantage to reduce energy consumption.

- Construction industry: curtain wall systems, roofing materials, etc., which are favored for their aesthetics and durability.

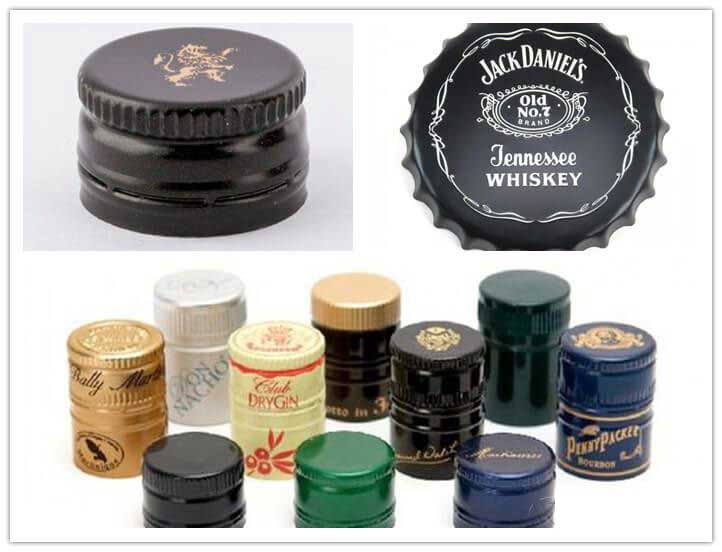

- Packaging industry: beverage cans, food packaging foils, etc., benefiting from their hermeticity and freshness retention.

- Electronic products: cell phone casings, laptop casings, etc., relying on their good heat dissipation and aesthetics.

In short, with the advancement of technology and changes in market demand, aluminium alloy sheet is expanding into new applications and developing in the direction of higher performance and environmental protection. In the future, we can expect to see more innovative use of aluminum alloy sheet products and technologies appear.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531