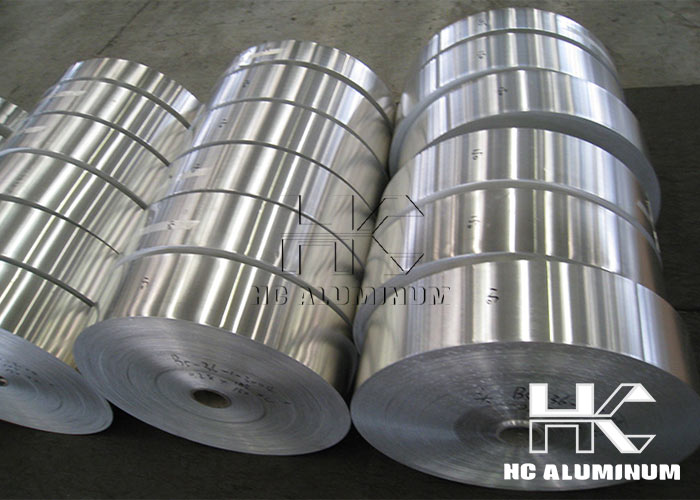

Aluminum Strip For Cable Shielding

Aluminum strip can be used as cable shielding material. Using aluminum strip as a shield in cables improves signal stability and transmission quality, especially in high-frequency applications.

Aluminum strip can be used as cable shielding material. Aluminum has good electrical conductivity and corrosion resistance and can effectively shield against electromagnetic interference (EMI) and radio frequency interference (RFI). Using aluminum strip as a shield in cables improves signal stability and transmission quality, especially in high-frequency applications.

Aluminum strip has unique advantages as a cable shielding material. Some of the reasons why aluminum strip is used as a cable shield are:

- Electrical conductivity and electromagnetic shielding properties

Aluminum has an electrical conductivity of approximately 61% of that of copper (International Annealed Copper Standard, IACS), which is lower than that of copper, but sufficient to meet the shielding needs of low and medium frequency electromagnetic interference (EMI) and radio frequency interference (RFI).

By covering the cable surface to form a continuous conductive layer, aluminum strip for cable shielding can reflect or absorb external electromagnetic waves, preventing the intrusion of interfering signals or cable signal leakage.

- Lightweight and Cost Advantages

Aluminum is only 30% of the density of copper, making it suitable for scenarios that require lightweight design (e.g., aerospace, mobile device cables).

Aluminum is far less expensive than copper, which can significantly reduce cable costs, especially in large-scale applications.

- Corrosion resistance and environmental compatibility

Aluminum forms a dense protective film of aluminum oxide in air, which provides excellent resistance to atmospheric corrosion and is suitable for use in harsh environments such as humidity and salt spray.

Corrosion resistance can be further improved by alloying or surface coating (e.g. tin plating).

- Flexibility and processability

Aluminum strips can be annealed to a soft state (O-state), making them easy to bend, wrap, and fit into cable structures.

Thin sizes (e.g., 0.1 to 0.2 mm) ensure shielding without significantly increasing the rigidity of the cable.

Aluminum strip for cable shielding needs to take into account the conductivity, flexibility and strength, common alloy grades include:

1. 1000 series (pure aluminum)

Typical grades: 1100, 1050, 1060, 1070

Composition: aluminum content ≥ 99% (1100 contains a small amount of copper, 1060 more pure).

Characteristics: Best conductivity (62~65% IACS), soft and easy to process, but lower strength.

Application: General shielded cable, low voltage power cable.

2. 3003 Aluminum Alloy

Composition: aluminum + 1.2% manganese (Mn).

Characteristics: higher strength than pure aluminum, good corrosion resistance, excellent formability, slightly lower conductivity (about 50% IACS).

Applications: Shielding for medium strength requirements, e.g. industrial control cables.

3. 8000 Series Aluminum Alloys

Typical grades: 8011, 8021

Composition: aluminum + iron (Fe), silicon (Si) and other trace elements.

Characteristics: higher strength, improved heat resistance, conductivity of about 50 ~ 55% IACS.

Application: Cables for high temperature environment or shielding layer requiring higher mechanical strength.

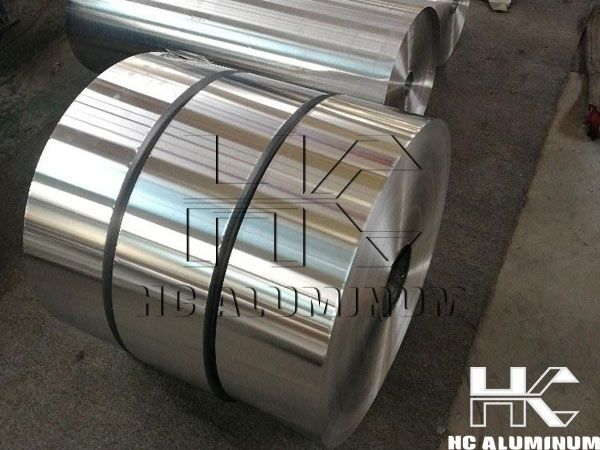

Cable shielding aluminum strip is usually used in the soft state (annealed state, O state), some scenes use “semi-hard state (H14/H24)” to balance the strength and flexibility, but the cable shielding is still mainly in the soft state. The reasons are as follows:

- Flexibility needs: soft state aluminum strip with high ductility, easy to tightly wrap the cable core, to avoid cracking or loosening of the shield.

- Installation adaptability: cable laying often need to bend, soft state aluminum strip can be deformed without permanent damage.

- Processing technology: aluminum strip through the cold rolled annealed to eliminate work hardening, to restore plasticity.

Cable shielding layer is usually used in the following forms:

- Single-layer aluminum tape winding: aluminum strip spiral winding or longitudinal package outside the insulating layer, lap fixed by adhesive or heat sealing.

- Aluminum-plastic composite tape (Al/PET): Aluminum strip and polyester film (PET) composite, both shielding and insulation, widely used in communication cables (such as CAT5/6).

- Multi-layer shielding: Aluminum strip is used in combination with a copper braid to provide both high-frequency (copper) and low and medium-frequency (aluminum) shielding.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531