Powder Coated Aluminium Sheet

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531

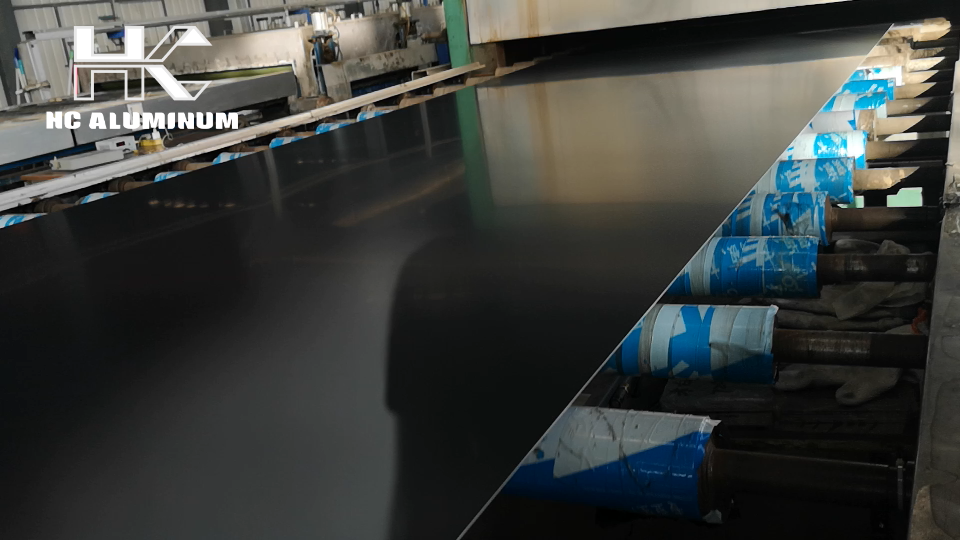

Product Introduction

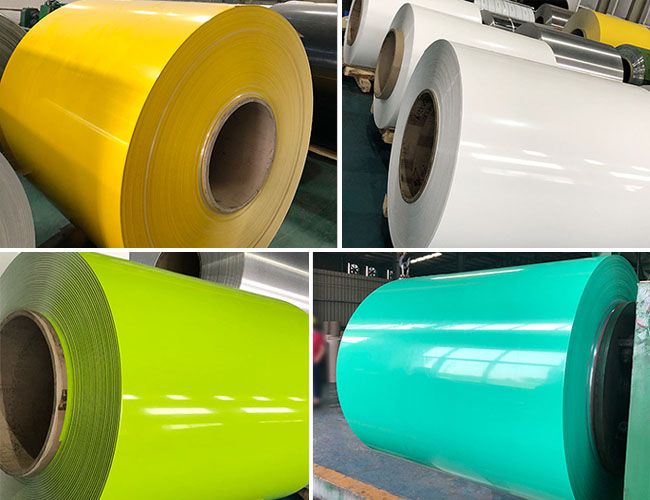

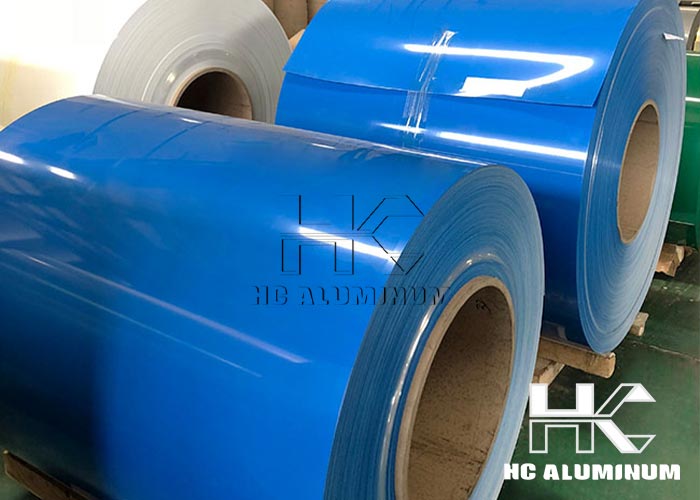

Contact UsPE/PVDF painting on powder coated aluminium has excellent weathering properties, colour-fastness and UV resistance. And is themost commonly selected finish for construction, giving long life and a virtually unlimited range of colors.

Powder coated aluminum sheet has advantages of rust and corrosion-resistance make them top choices for usage. Resistance to rust of powder coated aluminum sheet means that their durability is exceptionally long, also making them more easily reusable, especially compared to other materials. This property to withstand corrosion means that they are ideal for use in roofing and kitchen sinks.

The powder coating process involves the application of a dry paint powder which is charged electrically. The aluminium sheet being coated is treated and prepared to ensure maximum lifespan of the coating. With this technique, the powder is attracted to the aluminium including a contribution of a combination of static electricity to ensure adhesion. Following the process, the aluminium is placed into an oven of subsequent high temperature to melt the polyester allowing the finish to flow and cure. At the end of this process, the aluminium is cooled and is ready to be bonded.

Specification of powder coated aluminium sheet:

Aluminum alloy: | 1050 1060 1100 3003 3004 3105 5052 5754 8011 |

Thickness: | 0.016-5.0mm |

Width: | <2650mm |

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: | PVDF >=25micron, POLYESTER>=18micron |

Color standard: | E < 2 or it is not obvious by eyeballing |

Pencil hardness: | > 2HB |

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

T-Bend: | ≤2T |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |