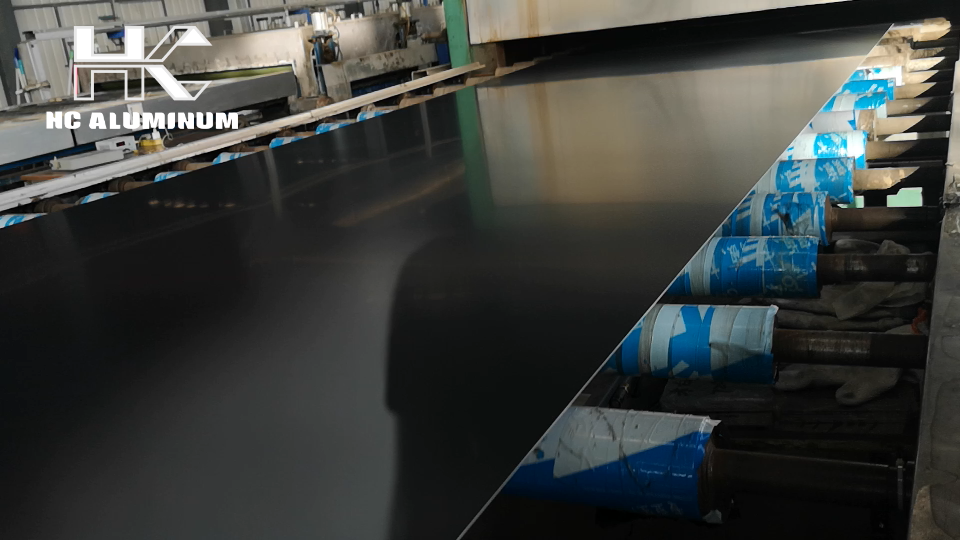

Black Powder Coated Aluminium Sheet

In the field of architectural decoration and industrial manufacturing, black powder coated aluminium sheet is becoming a new favorite in the market with its unique texture and excellent performance.

In the field of architectural decoration and industrial manufacturing, black powder coated aluminium sheet is becoming a new favorite in the market with its unique texture and excellent performance. As one of the core products of HC Aluminum, this material deeply combines the lightness and toughness of aluminum alloy with the aesthetic expression of powder coating through advanced technology, providing a solution with both practical value and artistic tension for modern space design.

I. Material process analysis

1. Substrate optimization

AA3000 series high-strength aluminum alloy sheets are selected, such as 3003, 3004. After precision rolling and stress release treatment, the tensile strength of the substrate is ensured to be ≥140MPa and the elongation is ≥5%. This material can achieve high-precision processing of ±0.1mm while ensuring structural stability, meeting the needs of complex curved surface modeling.

2. Powder coating process

The electrostatic powder spraying technology is used to evenly adsorb the powder particles on the surface of the aluminum sheet through a 90kV high-voltage electrostatic field to form a dense coating of 40-60μm thick. The key process parameters are controlled as follows:

- Pretreatment: After 7 processes including degreasing (40-60℃, free acidity 3-6 points), pickling (18% concentration, 40-50℃), phosphating (zinc system, TA18-25 points), etc., ensure that the coating adhesion reaches level 0.

- Curing: Melt leveling at a high temperature of 180-200℃ to form a three-dimensional network structure with a cross-linking density ≥ 85%, a pencil hardness of 2H, and an impact resistance of 50kg·cm.

II. Core performance advantages

1. Weathering and corrosion resistance system

- Salt spray protection: After 360 hours of neutral salt spray test (NSS), there is no rust or blistering on the coating surface, and the corrosion resistance is 50% better than the industry standard.

- UV protection: Add nano-level UV absorber. In the QUV accelerated aging test, the color difference ΔE≤1.5 after 500 hours, which is better than the traditional fluorocarbon coating.

- Chemical resistance: It exhibits excellent tolerance to acid and alkali solutions with a pH of 2-12, and is suitable for highly corrosive environments such as chemical and marine environments.

2. Environmentally friendly and economical characteristics

- Zero VOC emissions: Powder coatings do not contain solvents, and the VOCs emission concentration during the production process is less than 30mg/m³, which complies with the EU REACH regulations.

- Recycling: The aluminum substrate can be 100% recycled, and the separation recovery rate of the coating after special treatment is greater than 95%, which is in line with the concept of the entire life cycle of green buildings.

- Maintenance cost: The self-cleaning coating design makes the surface dust adhesion less than 5%, and it only needs to be washed with rainwater to keep it smooth and clean on a daily basis. The maintenance cost is 60% lower than that of traditional coatings.

3. Aesthetic expression tension

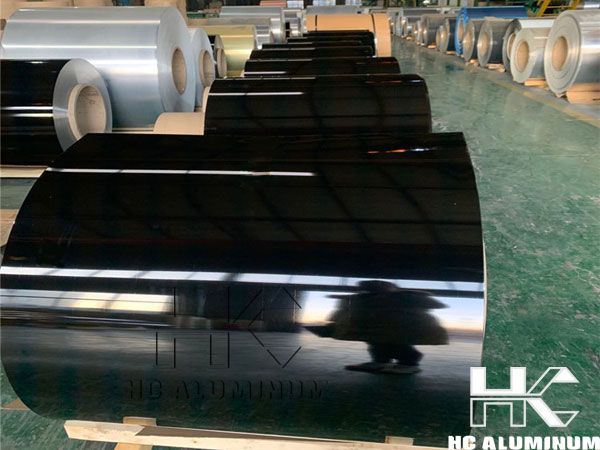

- Matt texture: By adjusting the powder particle size (80-120 mesh) and curing parameters, a delicate matte effect with a gloss of 60° and a gloss of 10-30GU can be achieved to avoid light pollution.

- Light and shadow effect: The black coating of powder coated aluminium sheet has a light absorption rate of more than 90%, and can create a strong sense of three-dimensionality and spatial depth with curved surface modeling.

III. HC Aluminum's Intelligent Manufacturing Strength

1. Full-process Quality Control

- Intelligent production line: Introducing a 480-meter fully automatic spray line and a Japanese Yaskawa servo conveying system to achieve precise control of spray pressure ±0.01MPa and film thickness ±2μm, and product consistency CV value <2.8%.

- Testing system: Equipped with professional equipment such as salt spray tester, colorimeter, gloss meter, etc., each batch of products has passed 12 rigorous tests such as adhesion and boiling water resistance (100℃ water boiling for 1 hour without peeling).

2. Large-scale delivery guarantee

- Capacity advantage: Annual production capacity of 1.5 million square meters, which can meet the centralized delivery needs of large projects.

- Supply chain management: Establish strategic cooperation with international brands to ensure stable supply and quality consistency of powder raw materials.

IV. Application scenario expansion

In the field of construction, black powder coated aluminum sheets are widely used in curtain walls, ceilings, shading systems, etc. In the industrial field, its corrosion resistance makes it the first choice for new energy vehicle battery shells and high-end equipment covers. In addition, in the design of commercial spaces, matte black aluminum plates create a minimalist aesthetic through the contrast of light and shadow, such as the immersive experience space of a luxury flagship store.

As a benchmark product of HC Aluminum, black powder coated aluminium sheets are not only an innovative achievement in material science, but also a concrete expression of industrial aesthetics. We take intelligent manufacturing as the cornerstone and technological innovation as the driving force to provide global customers with aluminum product solutions that are both functional and artistic. Choosing HC Aluminum means choosing the triple guarantee of quality, efficiency and sustainable development. Let us work together to shape the infinite possibilities of future space with the depth of black and the power of metal.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531